Modern electrostatic precipitators in ełk PEC. The next stage of investment

14 June 2017, Author: Cezary Wenda

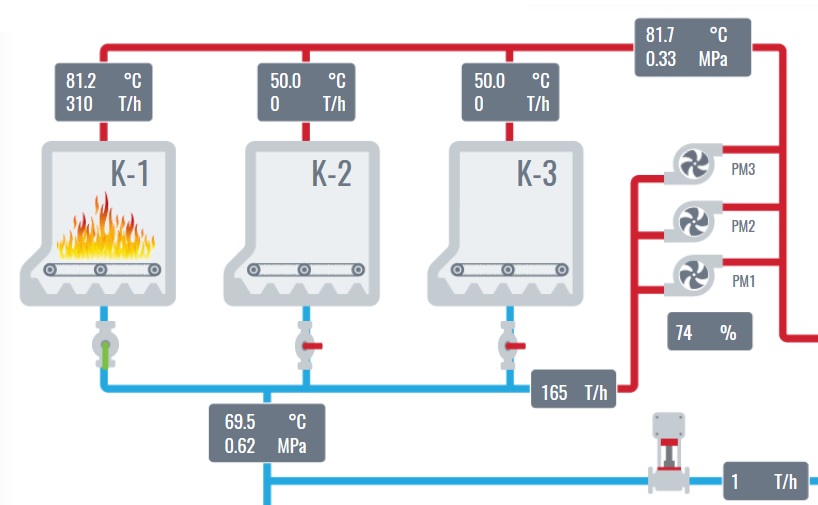

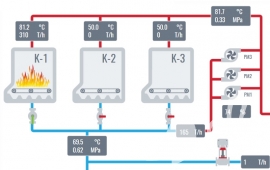

The investment involves replacing the existing, mechanical installation, dust collection, modern and more efficient installation based on the electro-filters. The modernization includes boilers No. 2 and 3. Expected date of completion of the investment is November 2017.

Has already been completed the first installation of the precipitator in boiler # 2. He worked throughout the heating season from the beginning of October 2016.

Currently work is underway related to the construction of the precipitator in boiler # 3.

· the shells an old installation of dust collection

· slabs are new foundations,

· After July 3, will begin installation of the precipitator,

· test is provided at the beginning of October.

Installation of electrostatic precipitators will eliminate dust emissions from the heating plant. The boiler # 1 will not operate acting possible reserve.

How does elektrofiltr?

The strength of the electrodes of the device are suitable for electrostatic dust molecules, and bulk electrodes that are grounded, attract the charged particles to prevent them floating to the chimney.

Electrostatic precipitators are assembled in Poland's largest energy sources – mainly applies to power plants.

More about the investment:

Technology is the most advanced method available in the technique of electrostatic precipitators. Electrostatic precipitators in the boiler # 2 are about half the price in the operation, consume half as much electricity than the existing installation based on mechanical cyclones. So it will not affect the cost of heat.

Elektrofiltr is continuously monitored (online) by the provider. Device working with feedback, are up to date on the effect of dust removal and consume exactly as much energy to keep the process on a given level of performance.

Dust emissions will be not higher than with boiler burning natural gas or oil, although in ełk PEC-u burned is coal. Dust emissions will not be higher than the natural content of particulate matter in ambient air, and so will not worsen his State.

The total cost of the investment. $6 million:

- 3.4 million-loan from the Provincial Fund for environmental protection in Olsztyn (interest rate per annum-1.2%), loan takes into account also the de minimis aid in the amount of $101 803

- own contribution-ok. 2.6 mln.

- News (3133) »

- Events happening in Ełk (1205) »

- Education (384) »

- Videos from the series Safe Elk (9) »

- Videos of the series happens in ełk (29) »

- Physical Culture Development Fund (1) »

- Investments (186) »

- Invest - aktualności (115) »

- Invest - projekty inwestycyjne (24) »

- Invest - tereny inwestycyjne (2) »

- About Coronavirus (97) »

- Culture (510) »

- In memory (9) »

- White Lily Award Winners (12) »

- NATO in Masuria (11) »

- Awards and distinctions for Ełk (25) »

- Awards and scholarships (34) »

- Deliberations of the Elk City Council (38) »

- Ngos (305) »

- Aid to Ukraine (54) »

- Improving the energy efficiency of buildings (1) »

- Clean Air Priority Programme (2) »

- Government Local Government Roads Fund (6) »

- Government Local Investment Fund (10) »

- Government Program for the Reconstruction of Monuments (2) »

- Revitalization (51) »

- Entertainment (670) »

- Anniversaries and celebrations (140) »

- Sport (347) »

- Obstructification and change of traffic organisation (62) »

- Obstructification and changes in traffic organisation (62) »

- International cooperation (16) »

- Adopt an Ełk dog (4) »

- Tasks carried out from the state budget or from state special purpose funds (1) »

- Green transport (2) »